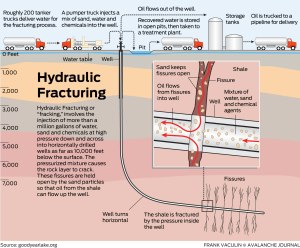

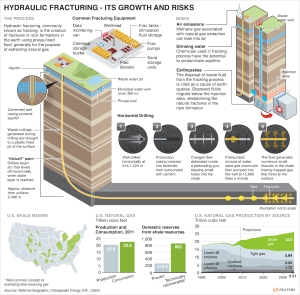

Hydraulic fracturing mostly known as “Fracking”is defined by Mindy Lubber, as being a method developed to improve the permeability of a reservoir by pumping fluids such as water, carbon dioxide, nitrogen or propane, at a level pure enough to cause the creation of cracks or fractures in the rock. The opening of natural fractures out the formation of artificial fractures in order to establish through the rock of pathways may allow the gas to reach the wellbore.

Why Do We Use Fracking?

When we submit a reservoir of oil or gas to hydraulic fracturing is to allow the drainage of oil or gas to be more easily between training that encloses and the wellbore. Indeed, natural gas represents a source of safe, abundant and economical energy to the planet. It has been used for several years, but the development of natural gas resources becoming more expensive; it requires the use of a special technology designed to facilitate the production of gas. Fracking is one of the main technologies developed for cost-effective production of gas.

Where Does Fracking Come?

The first discoveries of oil and gas seeps that were manifested at places of oil lying on the surface. At first, the exploration had as object to locate reservoirs which oil or gas flowed readily and actively to the surface. In recent years, the oil and gas have been extracted from reservoirs situated in different regions of Canada. Initially, these tanks produced abundantly and in many cases no appeal has demanded stimulus. This type of reservoir petroleum and natural gas called ” classic reservoir” characterized by a high degree of permeability and abundant production. Over time, many of these sources of oil and natural gas discoveries have been and are now in view of exhaustion. In most cases, new resources of oil and gas, in view of development are found in reservoirs which have a more difficult to produce. As a measure of the companies focus there efforts on these types of reservoirs that present challenges of production, susceptible to improve the ability of the flow productive technologies areas were developed. The most remarkable technological innovation took place after the Second World War, when techniques hydraulic fracturing was developed.

For several years now, the industry continues to develop new and improved and cost-effective measures to stimulate reservoirs by fracturing. The techniques that we use today in the field of exploration of shale gas do not differ significantly from those used there 60 years. A reservoir containing hydrocarbons is subjected to pressure exercised by the injected fluids at depth; this demarche causes cracking of the rock allowing hydrocarbons to easily reach the wellbore. The only parameter that has changes is where the techniques are used.

Forage complicated wells as vertical drill holes characterized by the presence in many walks of horizontal wells intersecting intervals rock considerable size containing the main type of drilling wells. It seeks to adapt existing technologies fracturing and being development has the most demanding environments to allow for profitable wells oil and gas.

How Does Fracking Happen?

According to the SCGNC, once the drilling and casing wells installed until the target depth, holes or perforations are drilled in the tubing to create entry points allowing the fracturing fluid and the suspension agent to penetrate one or multiple targeted oil zones. The number and orientation of the perforations are determined in advance a way of enabling them to cross any network of natural fractures that can conceal the tank.

The equipment used for hydraulic fracturing is then moved to the surface and connects to the wellbore in order to proceed to treatment fracturing. This method consists mainly four steps:

Step 1: Exercise of pressure on the rock tank by means of a fluid to generate the creation of a fracture.

Step 2: Workforce Expansion of the size of the fracture thus created by continuous pumping of fluid in one or more fractures.

Step 3: The fracturing as slurry in mixed fracturing fluid.

Step 4: Stop pumping and discharge of fracturing fluids into the well to allow their recovery, while leaving the agents in place in the tank.

The hydraulic fracturing process requires the use of a large amount of equipment on a short period of time. Depending on the size of the fracture treatment involving a single fracture can usually be done in one day. A team of fracturing installs the surface consists of multiple-pump units, of units of mixing, control units and sufficient in fracturing fluids and agents supply. These supplies are usually stored in tanks or containers to the same location of the wells. Once completed fracturing treatments, fracturing fluids flow back to the surface where they are subjected to a treatment for reuse or dispose in facilities approved by the Government. The equipment is then removed from service and the well location is freed unless other requirements necessary for the storage of fluids and equipment production. (SCGNC)

Environmental Consequences of Fracking

Hydraulic Fracturing is a very risky procedure for the humans and for the environment. Indeed, according to Doctor King’s research:

- For every injection of 15 000 m3 of water at 600 bar pressure for fracturing after sealing the well, there is an explosion of an explosive charge at the bottom. At an average of 10 explosions per well, this represents an annual consumption of 2750 inhabitants, and 5000 rotations per well tank trucks.

- For each fracturing, a tanker truck Hydrochloric acid. In contact with the deep limestone, the acid can expand the loopholes and facilitate dissolution ski fluid in the superficial layers.

- Ski products fracturing in groundwater by ancient faults and created by the explosion phenomenon facility in limestone by the addition of acid which can expand faults. Injected at 600 bars in depth, these fluids will all loopholes available to come to the surface.

- Released gas pockets that are created in the groundwater and soil by faults and frequent leaks in the concrete casing to the passage of groundwater in between 50 and 300 m depth

- Groundwater pollution (-300 m) by rising fossil natural arsenic (- 2000 m ) by mixing in fracturing fluids

- Air pollution by degassing and misting fracturing fluids so that they evaporate and not having to restate for the operator

Why So Much Movement About Fracking?

Hydraulic fracturing is facing controversy and taken opposite positions. Environmentalists argue strongly that fracking is dangerous and potentially harmful sources of water for our planet. Indeed, according to a PDF document “Non A la Fracturation Hydraulique” a growing opposition to fracking is widespread in the United States. The oil and gas industry is the use – or plan to do so – in 31 states, with more than 500,000 active wells across the country natural gas. States most affected are: Pennsylvania, Ohio, West Virginia, Oklahoma and Texas. The use of hydraulic fracturing and natural gas production are very poorly regulated at both the federal and at each state. At the federal level, the oil and gas industry is exempt from seven major environmental laws, including the law on drinking water, air act and the law on the protection of water. Hydraulic fracturing is an intrinsically hazardous process, making the lack of effective regulation is a recipe conducive to social and ecological disasters. Millions of Americans live work and go to school near natural gas wells and pipelines.

More and more evidence show that the production of gas, including the use of hydraulic fracturing and waste treatment, contaminated drinking water, air and soil, destroying the climate and provoking earthquakes. This creates risks and effects of concern on the health of residents in the United States. The growing popular opposition against hydraulic fracturing has led hundreds of cities and towns to enact bans on the fracking. The need to protect the Americans has lead PTCI not to undermine efforts to strengthen the regulations governing the natural gas industry, which aims to fill the existing gaps and to introduce bans and moratoria on hydraulic fracturing.

On the other hand, oil and gas companies are in agreement that using hydraulic fracturing to reach the deepest reserves of untapped oil and gas will always be an economic benefit and the benefit of hydraulic fracturing wins largely on the potential dangers. Furthermore, we must bear in mind that researchers conducting research on the site could have done the study using much higher than those normally maintained on drilling site standards. So therefore stresses the need for a well site to increase its monitoring and applying higher standards.

The Pittsburgh Example

In Pittsburgh, a recent federal study on hydraulic fracturing said that there is no viable evidence to support the claim that fracking contaminates drinking water aquifers on a drilling site in western Pennsylvania. After completing the site in question for a whole year, researchers reported that drilling fluids containing toxic elements remained in fact several thousand feet of groundwater.

Nothing seems to demonstrate that the process of hydraulic fracturing has contaminated water from underground tanks near a mine site in western Pennsylvania, concludes a study by the U.S. Department of Energy. (Www.energy.gov) Hydraulic fracturing is a very popular method to achieve deep reserves and extract gas that would otherwise be inaccessible. It is therefore imperative that higher standards be defined and followed.

Even though these are preliminary results – the study is not yet complete – they could give ammunition to the natural gas industry, which has suffered the wrath of various environmental groups and landowners who feel that hydraulic fracturing is a dangerous method. The researcher however warned that this study does not prove by itself that hydraulic fracturing was not polluting practices as geologists and those of the industry vary considerably in Pennsylvania and across the United States.

What regulations govern hydraulic fracturing?

The Gazette Officielle published an article on the laws of fracturing established by the countries of North America. It stated that the laws that were voted to regulate hydraulic fracturing.

- The fracturing of a well for the exploration or exploitation of oil or natural gas is prohibited within 400 feet below the base of an aquifer.

- The prohibition to perform a drilling exploration or exploitation of oil or natural gas at a distance of 300 meters from a safer removal of water in North America.

- The obligation to make a preliminary hydrogeological study within two kilometers of the proposed site to assess the potential impacts of drilling a well and its subsequent operation.

- The requirement to provide a minimum of three-observation wells groundwater within 100 meters of the drill site.

- The obligation to perform preventative monitoring of groundwater at the periphery of the drill site, conducting sampling monitoring wells 3 times per year for a period of 5 years after drilling, then once a year for operation and up to 10 years after the final closure of wells, in order to be able to respond quickly in the event of contamination.

- The obligation for the head of a stratigraphic hole to seal the borehole according to the rules of the art, the completion of the survey.

- The addition of standards for fracturing wells exploration or exploitation of oil and natural gas: The prohibition to achieve completion by fracturing a segment of a well within 600 meters of depth from the surface.

- The requirement to conduct a study to predict the propagation of fractures before realizing the completion of a segment well fracturing.

- The requirement to perform a tracking fracturing operations to ensure that the propagation of fractures is done as planned.

- In addition to this authorization, the applicant must conduct a hydrogeological study. And its wells cannot be less than 400 meters below the base of an aquifer.

- According to the findings of these studies, the protection zone could be extended beyond the standard 400 meters. In addition there is a requirement to conduct a study on the mechanical behavior of the surrounding geological formations before the completion of a well fracturing, as well as ongoing monitoring of fracturing operation.

Path Forward Of Fracking

The effects of hydraulic fracturing can vary greatly depending on the location of the drill site. Different types of rocks and other factors could create very different reactions and adverse effects. When hydraulic fracturing is a formation of more brittle rocks, fractures could potentially extend much further than expected and if it is not properly monitored and measured fluid could reach groundwater. That said, this situation is largely preventable when the care and time are taken to assess the progress of the drill site.

Rather than create controversy boldly approaching the whole subject, it is better to find workable and effective solutions that will benefit everyone, especially the locals who find themselves with hydraulic fracturing sites in their backyard. This must remain the priority. The safety of families and communities is much more important than the creation of economic prosperity value.

Drilling procedures stricter wells could be established, this would significantly reduce the potential hazards associated with hydraulic fracturing. Equipment and drilling fluids may also be designed with the safety and environmental sensitivity in mind. In addition, reuse water required during hydraulic fracturing procedures would reduce the negative effects that can potentially have this controversial method.